Shut-off flow rates:

The typical inflow rate into the dosing chamber needs consideration. The Flout you choose must be able to shut off (re-float) at this rate, otherwise the flow will pass right through the chamber.

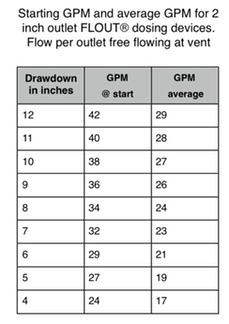

* Two inch Flouts need the flow to be 10 GPM or less to shut off.

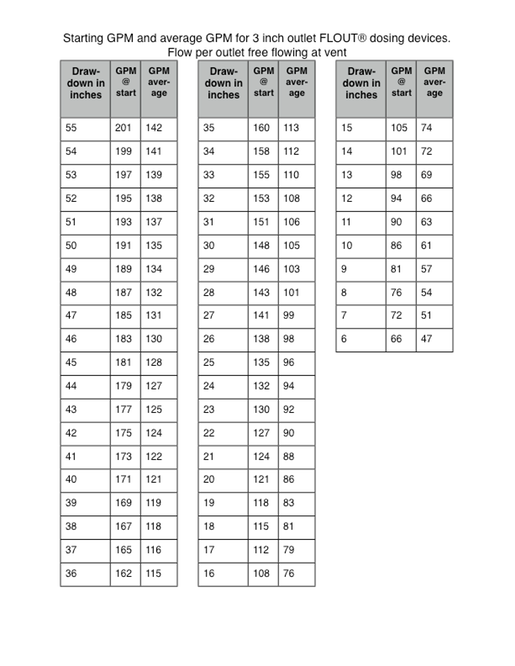

* Three inch Flouts need the flow to be 20 GPM or less to shut off.

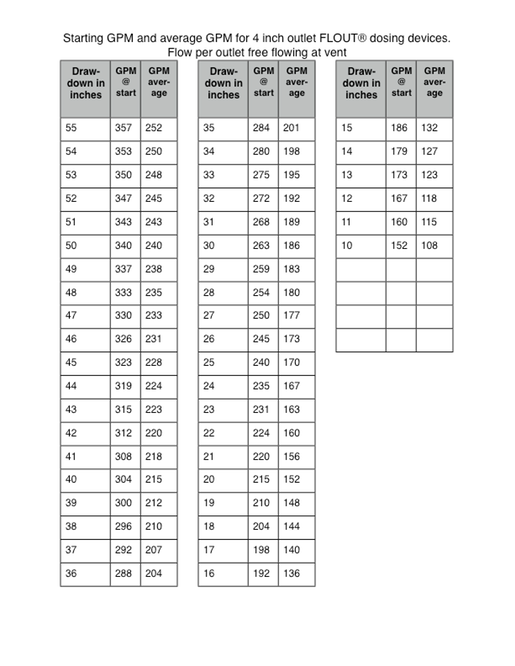

* Four inch Flouts need the flow to be 40 GPM or less.

The slower the flow, the quicker the shut-off.

How to deal with high inflows

* If a faster discharge rate is tolerable, use a larger size Flout or a MultiFlout

* Assure that the Flout does now drop below the outlet and provide additional slope to the outlet by shimming. 2-4%. Especially helpful with longer Flouts.

* Assure the discharge line leaving the Flout chamber has sufficient slope to quickly drain the Flout.

* Special ballast arrangements allow faster shut-off during higher flows.

With Pump Filled dosing chambers:

* High flow rate pumps can overwhelm the Flout. If inflows are kept below the recommendations above, the Flout can shut-off even if the pump is on. Bear in mind that liquid entering during the dose cycle will be included with the dose.

* Set the pumped volume from a pump chamber to slightly more than the Flout chamber capacity. The Flout will always start during a pump cycle and always be empty when the pump cycle starts.

* A Flout can be equipped to shut down a pump during the dose cycle. Once the cycle is complete, the pump re-starts after a protective delay.